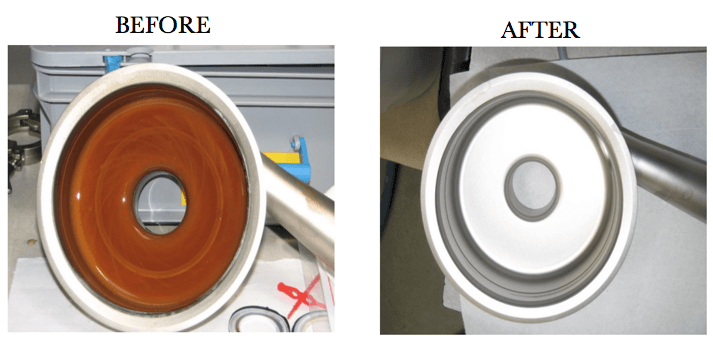

Diruneutra Derouging Service | Passivation With Diruneutra

on-site via our mobile servicing unit.

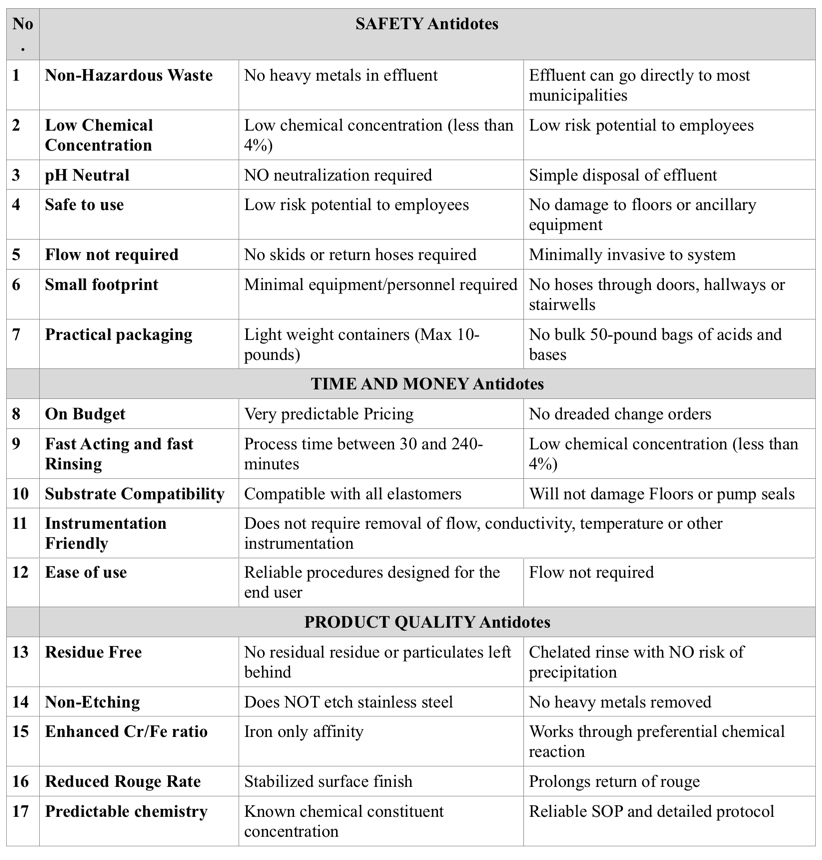

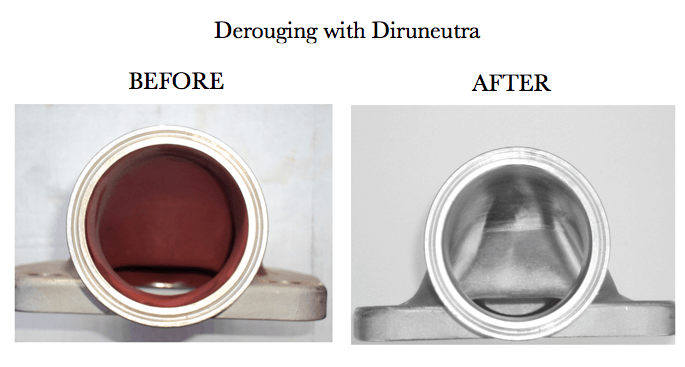

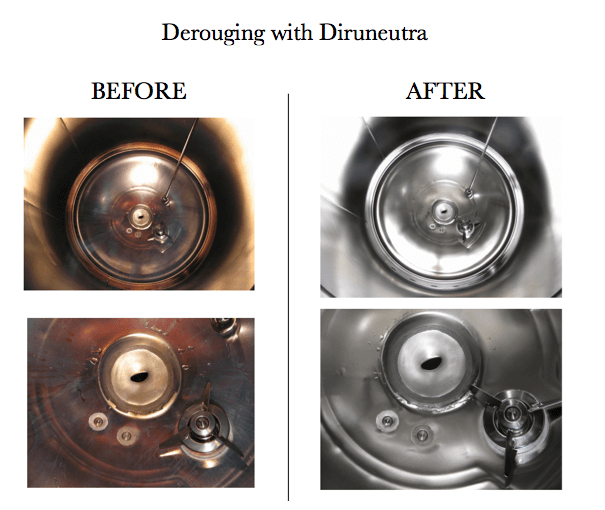

Diruneutra Derouging is helpful because it causes no harm to employees, floors or the facility.

No harm to equipment and it has a very simple JHA/JSA.

If you have questions or need a quote, please give us a call at (620) 842-3701.

How Passivation With Diruneutra Works

- Diruclean (NS) can be used as part of a pre-cleaning step if necessary. This pH neutral cleaning solution will remove oils, greases and other foreign materials from the manufacturing process.

- Diruneutra derouging chemistry (LIQ/P) removes iron byproducts (oxides and hydroxides) as well as free iron to enhance chromium on the surface Hydrogen peroxide is utilized to oxidize the surface and form a protective “passive” oxide layer.

- Systems that are already in places – i.e. components that can simply not be shipped out for servicing – can still take advantage of our acclaimed services.

If you can’t deliver your parts to us, we can bring our knowledge and experience to you.

Diruneutra Derouging Time Lapse Video

Benefits of Diruneutra Derouging Service

Safety

- Hazardous waste

- Chemical burns

- Chemical spills

- Pallets of fifty pound bags of acids and bases

- Hoses through doors, hallways and stairwells

The chemistry involved in Diruneutra Derouging is predictable, using a known chemical constituent concentration and there are no ‘secret’ proprietary ingredients. No bath chemistry adjustments or special additives and an estimated working volume.

Time & Money

- Over Budget

- Unexpected change orders

- Unnecessary process steps

- Turn key project durations of days or weeks

- Delayed or cancelled product campaign

- Floor stains or damage

- Long rinse times

The process times are short, it’s easier on budget, instrumentation friendly and easy to use. No hoses through doorways, hallways or stairwells.

Quality

- Residual chemical or particulates left behind

- Equipment damage due to severe etching

- Severe rouge production

- Insufficient Cr/Fe ratio

- Unknown chemical concentration and/or formulation

Derouging is non-etching as well. It won’t etch stainless steel, exacerbate rouge formation or remove any heavy metals.

Reasons Derouging Helps With Safety Risks

- Non hazardous waste

- Low chemical concentration

- pH neutral

- Safe to use

- Flow not required

- Small footprint

- Practical packaging

There is a low chemical concentration, less than 0.2% – so there is low risk to employee and it works through a chemical

reaction.

A Good Passive Layer

- The ASME Bioprocessing Equipment Standard requires a

Cr/Fe ration of 1:1 - A chemical passivation procedure shall be verified to meet

or exceed this minimum requirement. - This ratio may only be definitively determined by

performing destructive test. - A qualified procedure may be repeated to yield acceptable

results.

We Can Come To You – Applications Of Our Mobile Servicing There are any number of reasons that clients choose our mobile service over shipping to our facility. Some of these reasons are:

- Components are too large or heavy to ship economically.

- Components are too valuable to ship.

- Components cannot be spared for often extensive shipping times.

- Fixtures or vessels are permanently placed and cannot be moved.

- Discomfort with moving components out-of-house for financial or security reasons.

Whatever the reason, Celco is happy to oblige our clients. Our mobile servicing unit is always ready to come to you.